With an abundance of raw materials and resources, Africa needs to rapidly find new ways to generate greater value from its manufacturing industry which has been identified as a fundamental driver of economic growth.

Looking to disruptive technologies such as Artificial Intelligence (AI), bots, the Internet of Things (IoT), and machine learning, are revolutionizing industrial processes, and could save Africa’s manufacturing industry, where the adoption of technology thus far has been relatively slow.

In Kenya for example, the majority of manufacturers are still holding onto outdated production systems, according to a recent report launched by SYSPRO in conjunction with Strathmore University.

So why has Africa shied away? It’s simple, fear of job loss, inadequate infrastructure, an inefficient labour force and more so, lack of accessibility and affordability. All of which are a popular misconception.

The global landscape is changing at a rapid pace, for Africa’s manufacturing sector to keep up and gain a competitive edge, the industry needs to find ways to activate automation.

1 – Increased efficiency

Automation plays a crucial role in the digital transformation journey for manufacturers, enhancing their business environment for the better while improving supply chain management.

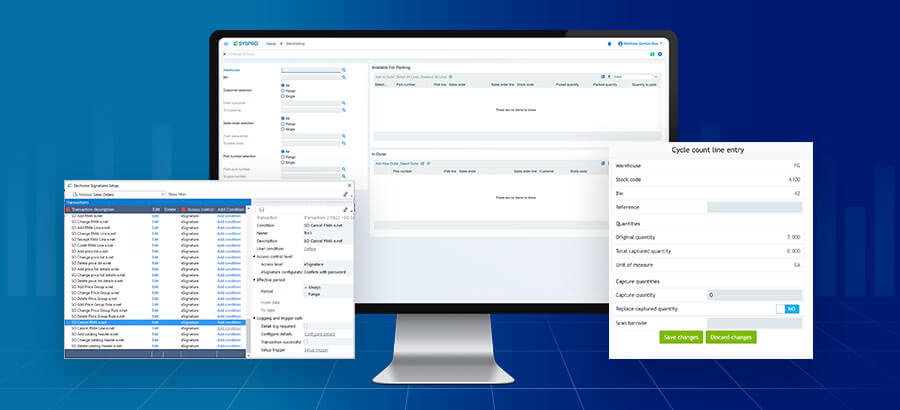

By plugging AI into ERP systems can reduce inaccuracies often felt throughout the supply chain, translating into better outputs for the whole business process. For example, enhancing the intelligence of what minimum order levels should be and at what stage orders need to be made.

Automating Africa’s manufacturing industry will not only remove repetitive functions, but see these jobs done more effectively and efficiently. With machines taking over the monotonous tasks, including basic accounting functions, manufacturers will see increased accuracy resulting in increased revenue.

2 – Increased productivity

Most of Africa’s manufacturers operate under capacity, and with valuable production time being lost comes lost revenue.

Manufacturing processes that are manually operated limit production, with faulty equipment causing downtime and a workforce who can only operate so many hours in a day are factors hindering the industry’s growth.

In fact, in Kenya, engines typically run for 86 days a year, with 50% only running three to five hours a week. If manufacturers increased this to 24 hours, they could achieve 12 months production in just three months.

By leveraging ERP systems automation capabilities, automated operations are known to perform tasks more efficiently than manual operations, not to mention, increase the rate of production.

3 – Reduced costs

With ERP systems and digital and automation capabilities, costs are reduced, so manufacturers, in the long run, will see a far greater return on investment (ROI).

Automation replaces the need for manual operations, so further cost savings will be felt by manufacturers with reduced overheads and labour costs.

4 – Job creation

Technology will see many jobs become redundant. But the reality is, technology is just changing the job landscape.

It’s true, the fourth industrial revolution will see the loss of 75 million jobs by 2025 but at the same time, technology will stimulate a further 130 million across the globe.

As the manufacturing industry evolves, new disciplines will require new skills. The industry needs to position itself for the future by upskilling or reskilling workers for tomorrow’s jobs. How? By taking advantage of resources that are readily available.

For example, SYSPRO Learnership Channel (SLC) provides training material to upskill individuals in ERP that can be accessed either on a desktop or mobile device.

5 – Embrace automation

In Africa, there is a need to educate the industry on new technologies, what they are, and how they can be effectively deployed within their business operations. Automation presents opportunities for forward-thinking manufacturers to capitalize on while diversifying products and increasing productivity.

Enabling automation with industry-built solutions such as SYSPRO ERP simplifies business complexities by providing an end-to-end solution for optimized cost control and enhanced business performance, positively positioning the industry for the next generation of manufacturing.