Following a six-month stint in a dining-room chair, glued to Zoom or my cell phone, I am now free. Now on lockdown level 1, I have managed to visit the office, had meetings with real people and I have even had my first beer during a bush break. While I bask in my newfound freedom, I can’t help but wonder why costs rose during the pandemic for certain industries. Could it have been unscrupulous suppliers?

Finding the true gluttons

For most, the weekly grocery shop has often been the only source of entertainment, until reaching the till. Costs for the weekly grocery shop were unreasonably high. At times I was looking at a 50% increase. Many stores placed direct blame on the supplier, yet if you take a supply-chain farm-to-fork approach you’ll find that cows haven’t stopped producing milk because of Covid-19.

My local beverage store also took a chance. Instead of adding 1% for tax after the budget to a bottle of wine, they added 20%. It’s a great business, great people, but what does that do for loyalty?

At the opposite end of the spectrum, a top retailer (the star retailer for my family I might add) offered easy online ordering, reliable SMS notified home delivery service, and value for money even considering new DC order-picking and other processes and thermal box costs –thank you.

Using technology to secure the supply chain

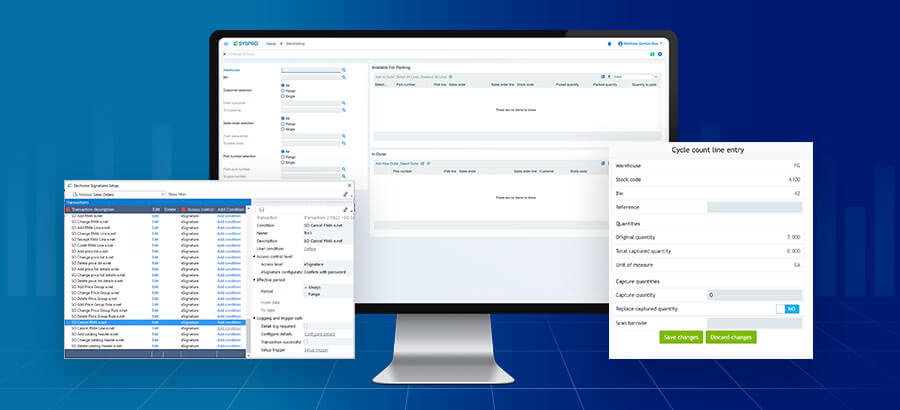

While the pandemic left many businesses vulnerable, with no choice but to accept the inevitable fate of poor service and shoddy supplier behavior, as a SYSPRO man, I see many places for Business IT to help.

1. Procurement

Supply Chain companies need to differentiate between preferred-suppliers with ethical/appropriate practices from the “not so healthy”. Technology can help businesses and reduce risk by helping to identify those preferred suppliers. Embedded AI can even assist businesses to predict when deliveries may be late.

2. Sales Orders

The rise of global lockdowns resulted in a bigger increase in online orders than ever before. Businesses therefore needed technology to keep track of stock and orders. Lot traceability could be used to identify, beyond quality issues and recall.

3. Logistics

The one certainty during the pandemic was uncertainty. Delivery quantities and processes were suddenly changing. Some businesses even looked into introducing new Uber-style delivery vehicles to keep up with the demand. Here organizations need technology such as ERP with low or no code tailoring and customization. Data should be available on any device and accessible from anywhere.

Take me back to the bush

Thinking back to my bush break, a lesson can be learned from my vacation host. Over 1000 people within her hometown in the Kruger Park were affected by the pandemic – the supply chain was destroyed locally. In response, other families with earnings became breadwinners for relatives and friends, ensuring survival.

Perhaps we can apply a similar approach to industry supply chains. Share the pain to survive and then seek the gain together. If the price of your business was impacted by the cost of material from unscrupulous global suppliers, perhaps there is an opportunity to source locally. In fact – there is an opportunity for manufacturing in South Africa for South Africa – I hope we as consumers make it happen.

Finding the best, most ethical suppliers can be a reality with ERP by your side. Let’s do it.