Answer agree or disagree to these two observations:

- The Coronavirus pandemic is going to change the way manufacturers operate.

- After the pandemic is over, we won’t be able to go back to doing things the way we used to.

If you responded Disagree to both points, you don’t need to read any further. However, if either of these points made you think how you will need to change, then read on. There is an answer, it’s not just a theory, and some companies have implemented it successfully. It’s about using information better.

The tipping point of change

In 2002, Malcolm Gladwell’s book The Tipping Point showed how some events can have a radical impact on society and act as the threshold to new views and ways of living and working. The Coronavirus pandemic has achieved just that in many ways. One has seen the sudden and huge adoption of working and communicating remotely. Applications like Zoom, which few people had heard of, have become a household word and technology. In many countries, there has been a significant growth in people using e-commerce. It’s likely that many of your customers who had never bought online before, now accept it as usual business.

What people have learnt in the last few months through the use of technology is that distributed working practices have made businesses agile and resilient, while those still stuck in the old ways have suffered. For industries such as manufacturing, that have sought to concentrate their operations for reasons of scale, the pandemic has taught that the cost efficiencies of scale have to be balanced against the advantages of agility and resilience.

But manufacturers can take heart because there is a solution that will allow them to become more agile and resilient, and improve quality, equipment efficiency, reliability, and decision-making. It’s the concept of Smart Manufacturing.

What is smart manufacturing?

Smart manufacturing (SM) leverages recent advances in technology and infrastructure that really haven’t been exploited by most manufacturers yet. Coined by the Clean Energy Smart Manufacturing Innovation Institute (CESMII), it is defined as :

“Smart Manufacturing enables all information about the manufacturing process to be available when it is needed, where it is needed, and in the form it is needed across the entire manufacturing value-chain to power smart decisions.”

SM integrates information from multiple applications and technologies that can be used to enable new solutions and better processes. It can be applied to a single machine line, an entire factory, or across a network of suppliers and customers.

It’s not just limited to big enterprises, organizations of any size can start on an SM journey. An SM operation includes some key factors:

- The Industrial Internet of Things

- Artificial intelligence and machine learning

- Connectivity

There are other technologies as discussed here in our Mint-Jutras-SYSPRO-Brings-Smart-Manufacturing-To-All-Through-Digital-Transformation-Report, but the value of these is still being determined.

The Industrial Internet of Things

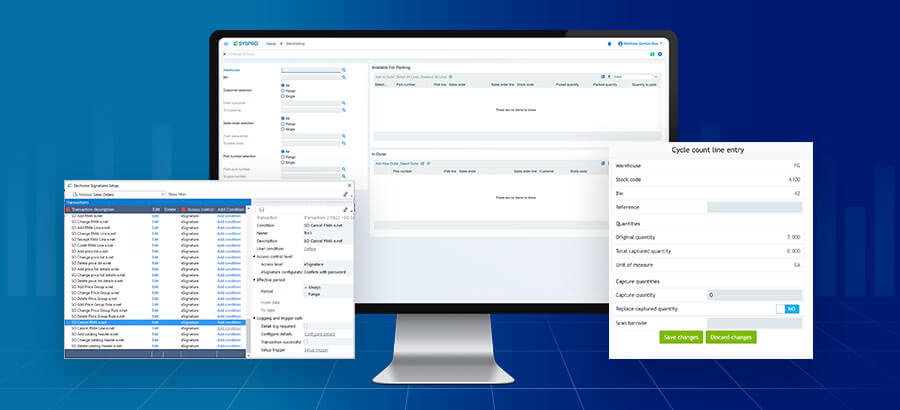

Industrial Internet of Things (IIoT) is simply the use of intelligent devices to collect data from manufacturing processes. For manufacturers, this concept is not new, but it’s the way the data can be used in the broader enterprise, rather than being limited to the plant floor, that is revolutionary. IIoT can play a part by connecting information from your machines and equipment to potentially make your manufacturing processes run more smoothly. Simply put, it’s the technology that allows you to connect your business instead of having siloes of disconnected information. Another part IIoT can play to enable you to make “smart” products, using that data to offer additional services that can benefit your customers and grow your business. Lastly, IIoT can allow plant supervisors to ditch their clipboards for tablet computers to monitor equipment, interact directly with enterprise applications, such as ERP systems, and collaborate more closely with other parts of the business. All of these capabilities provide the stepping-stones towards becoming a truly connected manufacturer.

When hearing about IIoT, many manufacturing executives start thinking about upgrading their equipment and then stop thinking about it when they count up the cost. There is good news, however. IIoT devices can be customized to suit your machine requirements using cellular and other mobile technology, giving manufacturers greater flexibility and control in how their implement IIoT.

Artificial intelligence and machine learning (AI/ML)

If you use some of the voices services now available, Siri on your mobile phone or Amazon Alexa at home, then you have experience with forms of artificial intelligence (AI/ML). These technologies don’t offer value on their own, they need to integrate and inter-operate with other systems in the business, like an ERP or IIoT system.

AI/ML enable smart manufacturing by checking machines, orders, and processes in real-time. This can provide information and insights that manufacturers could not normally get in quick enough time to plan or act because it was too time-consuming to analyze the data.

Some other benefits that AI/ML can offer include:

- improved reporting: this is not just faster information but raising and answering questions you may not have considered asking

- fraud detection and working capital optimization: this can be achieved by integrating AI/ML with your accounts receivable and accounts payable

- Trend detection: until only recently specialized personnel could analyze and seek out trends, now artificial intelligence can deal with this

Connectivity

No organization runs a single application today, and no application can afford to be an island. Applications need an application program interface (API) to extend or integrate with others.

A smart manufacturing operation needs to connect different sub-systems from the shop floor to the product design office, accounting, sales, and the supply chain, so a set of APIs must be available to make this work. Then looking beyond the enterprise, you need to have connections via the cloud to enable seamless integrations with e-commerce platforms as well as the systems used by suppliers and customers.

Smart manufacturing opens up new areas of innovation

SM can open up new areas of innovation that allows a manufacturing operation to create higher quality products, improve productivity, increase energy efficiency, and sustain safer plant floors. Furthermore, smarter factories also offer the opportunity to boost employment. As businesses adopt SM, new technology-based manufacturing jobs will arise, creating direct manufacturing and non-manufacturing employment. Having SM capabilities enables an enterprise to be more responsive to customer needs and can be critical to meeting customer demands for more customized products. SM will enable employees to control a higher number of machines. Through the combination of AI/ML and IIoT, manufacturers can have a clearer insight into predictive maintenance and lower maintenance costs.

Essentially, SM is a network that can communicate key information about your company’s operations in real-time and enable collaboration and feedback. Imagine how you could improve on your business, product quality, sales, customer service, and internal communication with SM.