As far as food recalls go, what a busy year it has been. In North America, the food and beverage industry has seen a massive increase in the units recalled. The USA is experiencing a 92.7% spike in FDA recalls and an 83.4% increase in recalled pounds – cited by USDA, since 2012.

Most recently, here in Canada, we have all been affected by the massive romaine lettuce recall, and even over the past few days kale was seeing a massive upturn in sales due to the recall of romaine, but now kale has been recalled over possible Listeria contamination in Eat Brands salad shake ups kits as confirmed by the Canadian Food Inspection Agency (CFIA). Our pets are also at risk; at the time of writing this blog, eight dog food brands are being recalled due to potentially deadly levels of vitamin D.

These are just a few recent examples of why it has never been more important for suppliers, processors, and retailers to have business systems in place that can trace back, trace forward and detail any modifications you did to the product throughout its lifecycle. We call this traceability – also known as tracking farm to fork.

For manufacturers, your livelihood is based on your ability to efficiently and profitably produce, sell and ship product. When a recall occurs, the regulations require you to publicly announce the recall. Depending on the scale of the recall and if there is subsequent litigation, sometimes the financial and reputation impact of a product recall is insurmountable. Many small companies have declared bankruptcy as a result of the recalled product. Larger corporations with more financial flexibility must work quickly to maintain customer loyalty and most importantly, shareholder confidence.

How do you protect your business and minimize the impact of a recall?

- First off, make sure you have a good Food Safety Plan in place.

- Secondly, perform “mock recalls” regularly, time them and ensure you are meeting both the regulatory and supply-chain partner requirements for completion.

This “time to completion” is dramatically reduced by having the right business systems in place to make reporting data available – where your raw materials came from, where you shipped your finished goods and what modification/assembly did you do in the middle. The industry standard system for this type of data collection, storage and reporting is known as an ERP System (Enterprise Resource Planning).

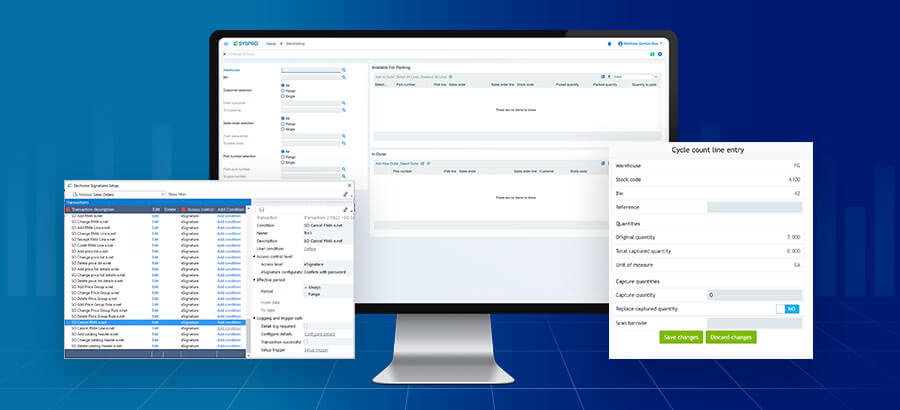

An ERP system can be successful at delivering the right traceability information by extending its reach down to the plant floor or integrating it with your other systems tied to your manufacturing such as MES (Manufacturing Execution Systems) and WMS (Warehouse Management Systems).

Some ERP systems are designed for more financial functions, while others like SYSPRO are designed for manufacturers. Manufacturing ERP systems are designed for companies that purchase, assemble/produce (WIP), weigh/label product – a staple for the food industry, and sell by weight or unit for enabling trace back to each individual piece that makes up the product/or the recipe.

By capturing this data end-to-end, your ERP system has “traceability” built in. This built-in traceability and reporting makes it quick and easy to get the trace back reporting you need. It’s a matter of simply running the right reports. This reporting dramatically reduces the time to complete the recall and therefore helps to minimize the financial and negative brand impact. Maintain the confidence of your customers and/or shareholders by mitigating the adverse effects and media attention of the inevitable recall.

Given space limitations, in my next blog I’ll talk about how you can use traceability to make more money!