Having looked at the ten reasons why an ERP system can help manufacturers, let’s look at manufacturing-specific functions that an ERP system can offer.

Best Practice is to have manufacturing connected within the overall business; too often we see businesses with manufacturing disconnected. The value of an ERP system is that the manufacturing elements are integrated with the rest of the business. This allows for more streamlined and efficient processes, and ensures that all departments are moving in the same direction and not just doing their own thing.

An ERP solution can integrate the manufacturing value chain, helping with functions from planning and sourcing, scheduling and shop-floor control, to quality inspection and maintenance. The ERP system automates business processes across the business, connecting people with those processes to support business goals, and making sure company assets are being properly and efficiently used.

Material requirements planning (MRP)

The MRP is a system that calculates the inventory needed for production and drives procurement to ensure that items are ordered in time. Managed properly, the MRP can optimize material and product levels. It improves the efficiency, flexibility and profitability of manufacturing operations. As part of an integrated ERP system, it automatically gets updates from sales orders. Therefore it can help manufacturers to respond more quickly to changing demand and avoid production delays and inventory stock-outs. Without an automated MRP, it is difficult for manufacturers to be responsive and adjust manufacturing operations.

Benefits of MRP

The benefits of an MRP include:

- Reduced customer lead times and therefore improved customer satisfaction;

- Reduced inventory costs;

- Effective inventory management and optimization;

- Improved manufacturing efficiency;

- Improved labor productivity;

- More competitive product pricing.

Master Production Schedule

The Master production schedule (MPS) allocates available resources to production processes and provides the schedule for individual items to be produced in a given time period.

- It is used to plan the use of factory equipment, shop floor workers, and processes.

- It creates an efficient process for production, organized around customer and organizational needs.

- It can minimize the lead time between the placing of an order and the completion and delivery of that order.

- It optimizes both customer-dependent processes — such as on-time delivery — and customer-independent processes, like production cycle time.

Manufacturing Operations Management

In the connected manufacturing environment of the modern business, a manufacturing operations management (MOM) system is needed to automate and manage the performance of all business processes in the manufacturing plant. As part of an integrated ERP solution, it can synchronize maintenance and reduce maintenance costs, increase equipment uptime, and improve manufacturing productivity. It can also streamline time and attendance tracking and eliminate paper tracking and manual data entry.

Engineering Change Control

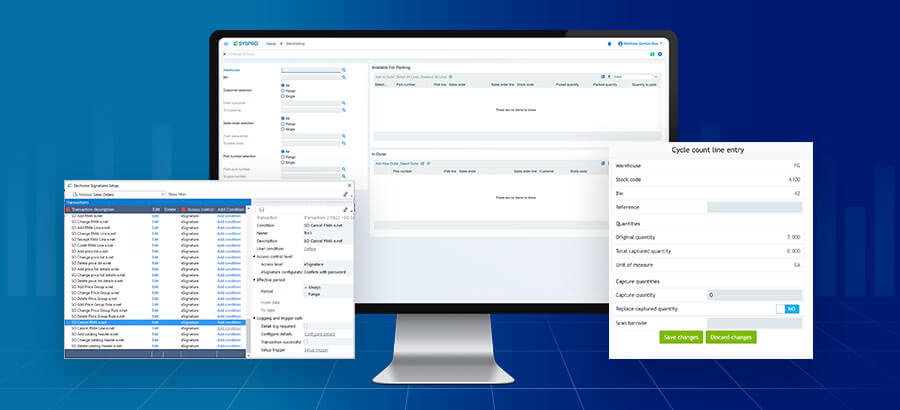

When a product is being designed or changed, there needs to be a way to ensure product quality and to see how design changes will affect production costs and pricing. Rather than a paper trail, it is better if groups involved in design and production are electronically notified about actions or responses that are required before any changes can be approved. Once approved, these changes should automatically feed into the production system, as well as other areas such as procurement.

Traceability

Manufacturers increasingly need a system that tracks materials from receipt, through production to delivery, offering visibility throughout the value chain to ensure quality and to assure compliance. An integrated traceability system enables manufacturers to trace, identify and report on items in every part of the supply chain. Should a product recall be necessary, the traceability system should enable a fully compliant recall process to happen and minimize the impact of the recall on the business.

Why use an ERP system in manufacturing?

An ERP system integrates all business functions into a single system, allowing manufacturers to automate processes, eliminate silos in the business, and make data-driven decisions to drive business growth. Specific functions that a manufacturing-oriented ERP solution provides can improve efficient use of machinery, ensure interruptions to production are eliminated, reduce costs, and streamline processes. With this solution, manufacturing collaborates with the rest of the business to improve quality, increase customer satisfaction, and grow profitability.