For manufacturers that have grown up from a small business, with a handful of employees and few customers, to one with many staff and customers, there comes a time when the business software needs of the company have to be re-evaluated. No longer will spreadsheets and simple accounting packages do; neither will outdated incumbent ERP applications that do not support modern business needs.

Here are ten reasons how an ERP system can help manufacturers.

1. Integrated business

A big benefit of an ERP solution is business integration. It unifies people and business processes to improve daily operations. It also provides insights into how assets of the business, such as inventory, are being used. If departments work in silos, this can significantly limit how well the business operates and the ability to use information to make smart decisions. An ERP system brings financial, manufacturing, and business data into one central place so staff and management can have a complete view of how different business areas are working in real-time. It provides visibility into areas that are, or are not, working optimally. Data from the system can then be used to track how corrective actions are making improvements.

2. Eliminate manual data capture

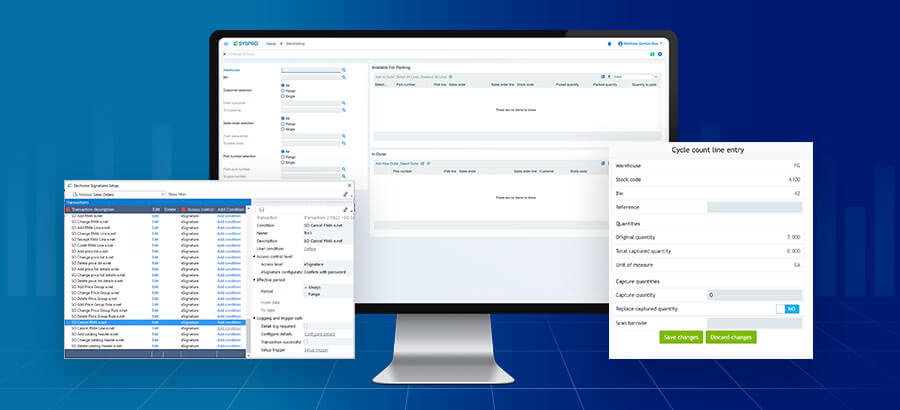

If staff repetitively input data manually, this not only wastes time but also increases the risk of human error. An ERP system allows data to be captured once, freeing up staff to focus on more value-adding, business-critical work. Increasingly ERP systems are now being used to capture information electronically, in real time, such as from sensors on equipment, or by scanning barcodes as items are received from suppliers

3. Automation

Another benefit of an ERP system is the ability to automate different operations within a business. Business processes can be automated to improve workflow, and information can flow automatically between different areas of the business — for example, from customer order, to inventory procurement, to production job scheduling, to invoicing and to warehouse shipment. No manual data entry is needed; this means no duplication of work.

4. Optimized manufacturing and shop floor data collection

As manufacturers begin to digitize the factory floor with sensors and other devices track machinery activity, they need a system to help manage this information to gain greater efficiencies. The manufacturing optimization features within an ERP and MES system can be used to uncover problems, and identify opportunities to increase labor productivity, reduce machine downtime, increase manufacturing throughput, and bring down waste in the manufacturing process.

5. Optimized inventory

An ERP system typically allows manufacturers to reduce their inventory costs and capital tied up in inventory. Integration of procurement, production and inventory means that purchase orders can be more accurately linked to what is needed to replenish current stock so that production is not impacted. This information can keep inventory levels optimized to avoid common problems of over- or under-stocking and wastage due to the holding of obsolete stock.

6. Improved customer service

Because an ERP system allows information to be shared between departments, customer service can be improved. Whether it be confirming a customer order or a complaint, sales or service staff can easily access sales account information to understand more about a customer’s purchase history. Quick data access also means faster response times, improved order accuracy, and smoother deliveries.

7. Better supply chain management

An automated and integrated ERP system enables more accurate and timely procurement, inventory tracking and management, logistics and fulfilment. It helps to speed up order capturing and fulfilment by bringing together sales, customer service and finance to move orders through the manufacturing supply chain.

Integration with supplier deliveries means greater visibility throughout the supply chain. Real-time supply chain data helps identify bottlenecks that could impact production work and customer orders.

8. Improved accounting and cost efficiencies

A key part of an ERP system is that information is collected automatically from different operations of the company, and incorporated into accounting records, such as accounts payable, accounts receivable, general ledger, and budgeting. For standalone accounting systems, this information has to be generated by other departments and then captured manually into the financial system. An ERP solution automates the collection of financial data, decreasing the time to produce monthly financial statements.

An ERP system streamlines business processes and integrates the data from them, providing a more comprehensive understanding of costs. This means the necessary corrective actions can be taken to reduce costs and make operations more efficient.

9. Better reporting and collaboration

Managers need real-time, accurate data to make smart decisions. An ERP system includes built-in reporting tools that gather data instantly from across the enterprise. Decision-makers can therefore be assured that they are working with the most recent and relevant information. It also allows staff on the shop floor to better plan and manage the work that they do.

With an ERP system, staff can get the information they need to do their job without hunting for it in another system. This means less time searching through data to find the information needed. It also makes it easier for departments to communicate and collaborate with one another.

10. Clean environment

Manufacturers are increasingly being required by customers and legislation to reclaim discarded outputs through recycling and reuse. As companies move to more a sustainable footprint, they will need to gather data on the full range of their activities, from the original sourcing of materials through the end of the product life cycle. An ERP system can operationalize the processes and systems for collecting and reporting on how a business is meeting its goals for a cleaner, more sustainable environment.

Why manufacturers need an ERP

As a manufacturing company grows, it needs to adopt practices and systems that will enable it to scale. Sticking with spreadsheets, simple accounting applications, or disparate siloed systems, will limit the company’s ability to handle growth effectively, and will therefore negatively affect customer service and profitability. By integrating the organization with an ERP system that has been built by manufacturers and is designed for manufacturing, the company can ensure it has the optimal software solution to enable continued growth.