Although the term was coined as early as 1999, the Internet of Things (IoT) has only really become a comfortable part of our vernacular in recent years. As manufacturing factories become increasingly smarter, technology-driven real time optimization of manufacturing production has become a reality.

The Industrial Internet of Things (Industrial IoT) refers to the use of the IoT technologies specifically in the manufacturing industry. It is this next wave of innovation that is impacting the way in which manufacturing organizations conduct business, structure supply chain partnerships, manage demand and run plant operations.

The Industrial IoT combines mechanical systems with electronics to “connect” all aspects of the manufacturing process. Specifically, it makes use of internet-enabled devices and factory equipment to collect, monitor, exchange, analyze, and implement information that is fed back to the organization, including plant managers and senior management—in order to make real-time, fact-based, informed decisions about the business.

The issue that many of today’s manufacturers face, when it comes to the Industrial IoT, is not knowing where to start in their technology needs and business processes, in order to maximize the impact of their investments.

Identifying the business benefits is the first step to leveraging Industrial IoT-enabled processes for business growth. Here are the four key advantages that manufacturers should consider:

- Real-time insights and notifications

Internet-connected machines and devices allow data to be captured and broadcasted to shop floor managers in real-time.

For example: a food manufacturing plant can proactively monitor and react to instances where production temperatures rise and fall out of an optimum range.

- Connect the shop floor to the top floor

Collected data can easily be transmitted to senior management and sales teams in real-time. This offers greater visibility into plant operations and allows for quicker, more informed decision making.

For example: a salesperson is immediately notified about delayed orders and can communicate timeously with customers to manage expectations.

- Improve supply chain alignment

Data can extend beyond the manufacturing company, into the supply chain and be shared with key suppliers.

For example: Smart machines let suppliers know when inventory is running low triggering stock replenishment before critical levels are reached.

- Enhance customer experience

Customers are easily notified about the progress and delivery of their orders without any manual intervention.

For example: GPS-location tracking on the order itself to bypass reliance on factory staff or delivery drivers to update information.

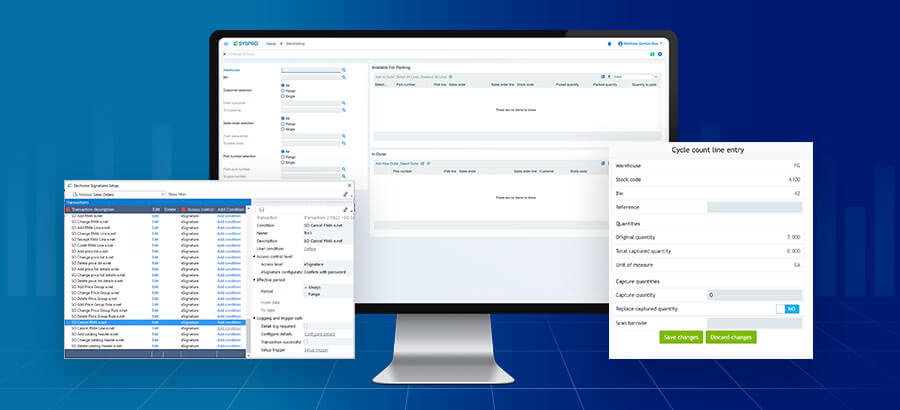

How does SYSPRO enable IoT?

A major focus of the Product Innovation team at SYSPRO has been to enable easier access to SYSPRO data for transaction and display purposes from anywhere. The SYSPRO Windows Communication Foundation (WCF) Service supports both representational state transfer (REST) and simple access object protocol (SOAP) based communication methods which makes access to SYSPRO possible regardless of the platform. This allows for full integration of IoT devices with SYSPRO in a controlled and secure manner.

The Product Innovation team has also recently focused on putting together some proof of concepts and prototypes with common IoT devices to provide developers with a head start and best practices for their IoT development.