The global pandemic is forcing everyone to reassess their inventory management processes. A recent bulletin from the Cleaning and Hygiene Suppliers’ Association (CHSA) has called on medical supply businesses to urgently address their supply chains and plan for shortages. Discussing the impact of COVID-19 on the cleaning and hygiene sector, it cited the fragility of just-in-time supply chains, reduced production capacity, and unprecedented demand as major contributing factors to global supply chain struggles.

Coronavirus and subsequent national lockdowns have caused considerable disruption to production processes across all sectors. This disruption is hugely costly and is a real threat to just-in-time delivery models. At the same time, demand for many products has become unpredictable, leaving suppliers uncertain as to whether products have been used or allocated to stock.

The bulletin reveals just how tough inventory management is at times of supply chain disruption and unpredictable demand. That critical business function has now become a major talking point in the C-Suite. As businesses grow, their levels of inventory also increase and for a lot of manufacturing firms, up to 50% of capital resides in inventory. As the cost of materials continues to fluctuate, the link between effective inventory management and cash flow has never been more important. But how do you manage inventory effectively to ensure goods go to the right place at the right time, on time?

Accurately control stock

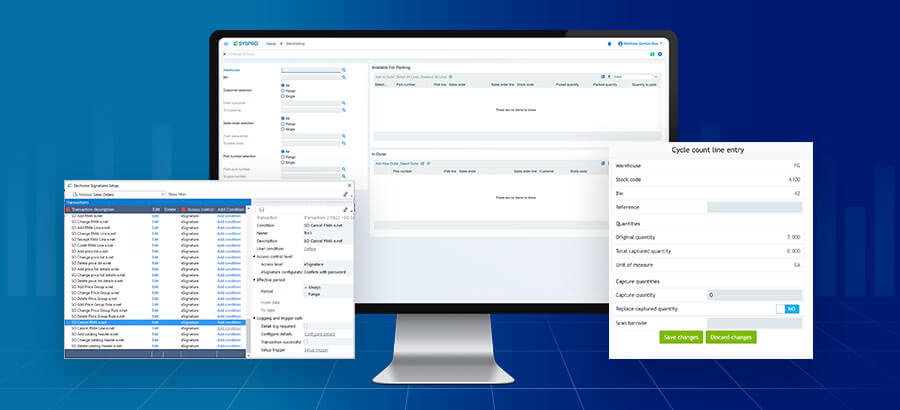

An ERP system can help business better manage inventory with solutions like SYSPRO’s Inventory Management which help to coordinate the actions and requirements of a business so that stocks are maintained at the right place, at the right time, and in the right quantities to satisfy the demands of customers or of a production process. Using an ERP system to manage inventory will assist with a number of goals.

Go lean

A Material Requirements Planning (MRP) system in your ERP will help customers alleviate some of the headaches typically associated with the excess component, work-in-progress, and finished goods inventory. By providing a comprehensive view of demand and supply and identifying key trends, it is possible for inventory managers to link orders, lead times, and time fences for more accurate just-in-time-based materials replenishment. They can then reduce the costs associated with expired or unpurchased stock levels. Efficient automation, management, and the tracking of product life cycles take place within the Inventory, Bill of Materials and Engineering Change Control modules of SYSPRO, accelerating the go-to-market process and accelerating delivery.

Better manage product recalls

Effective and efficient inventory management can also help manufacturing businesses to better respond to and manage recalls. ERP inventory management capabilities should enable warehouse managers to quickly identify products affected by a recall and filter inventory levels based on criteria including expiry dates or batch numbers. When all this information is stored and kept updated within the ERP system, action can be taken quickly to minimize damage to customer relations and rapidly dispatch replacement products.

Plan for tomorrow

Nobody can be certain what tomorrow will bring but we’re likely to see more erratic supply and demand, breakdowns in supply chains, and highly volatile inventory costs. A comprehensive ERP inventory management solution can lighten the load by providing greater visibility of supply chains and enhanced planning capacity thanks to accurate information on inventory, orders, demand, and market changes. One thing we can be certain will remain the same is that customers will expect to receive the right product at the right place at the right time, on time, every time. Those savvy businesses that leverage technology to respond effectively will be the ones leading the charge