As a consequence of all the chaos and disruption caused by the pandemic and humanitarian crisis in Ukraine, the supply chain of manufacturers and distributors worldwide are going to be under greater pressure from both industry and competition to increase their domestic production, grow employment and reduce their dependence on sources that may be a risk to their operations.

High and increasing costs, in combination with long recovery times, have triggered many companies to reassess their customer service plus supply-chain strategies and footprints to make them more resilient to any kind of disruption.

Manufacturers and distributors will need to rethink their use of lean manufacturing strategies that minimize their inventory held by optimising the inventory mix required to protect customer service in their global supply chains. The challenge for companies will be to make their entire supply chain more resilient without weakening their competitiveness.

Reducing risk in supply chains

By gaining a better understanding of their business and where the risks lie within operations, organizations are able to adapt and remain resilient in the face of challenges. This entails going far beyond the first and second tiers and mapping the full supply chain, including distribution facilities, warehouses and even transportation hubs. While this may seem unnecessary when everything is stable and predictable, one surprise disruption in one part can always bring serious repercussions.

In response to supply chain disruption, many organizations are now beginning to diversify their supplier base. In other words, local manufacturers should start finding partnerships with local suppliers.

Ensure supply-chain visibility

Having visibility across the supply chain means organizations are able to better establish an accurate list of components determining the origin of supply and identifying alternative sources. In come cases where tier-one suppliers do not have visibility into their supply chains, always. They can factor in risk of supply and plan such mitigation before it occurs.

The procurement process doesn’t start with raising a purchase order and sending it to a supplier. It starts before that. For a business to re-imagine and transform its procurement process, it needs to examine how the main processes of strategic sourcing (Source-to-Contract and contract pricing) for the large suppliers and supplier groups then operational procurement (Procure-to-Pay for the non-strategic items) are implemented in an integrated way, and not just how an old-style procurement department performs them.

Implementing a procurement strategy

The obvious way to address heavy dependence on one medium or high-risk source (a single factory, supplier, or region) is to add more sources in locations not vulnerable to the same risks. Then increased collaboration with suppliers and customers is critical to make these relationships work effectively for the whole supply chain – remember you are not their only customer in trouble when disruption hits.

Procurement can be a significant driver of an organizations pandemic recovery efforts. Forward-looking companies should be looking at how procurement can be enabled with technology solutions to make it more effective and enhance the value that it can deliver.

The ability of procurement to quickly update orders in response to a sudden change in customer demand is simplified if there is visibility and communication within the supply chain. For example, if a customer moves an order forward, the near-term delivery agreements with suppliers can be updated to get raw materials sooner. Effectively managing safety stocks between manufacturer and supplier. A manufacturer will usually keep products only used by them, while the supplier holds those items supplied to many manufacturers. The procurement function needs to be agile and ensure stock is available for production.

Building resilience for the future in supply chain

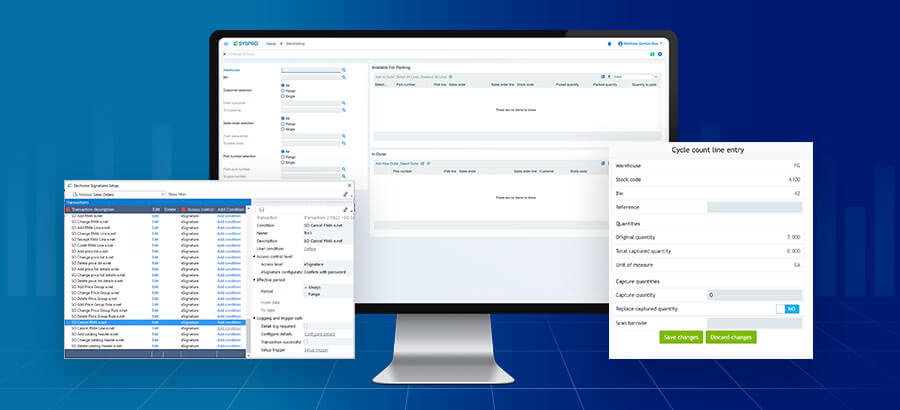

Once the immediate risks to a supply chain have been identified, leaders must then design a resilient supply chain for the future. During this process, digitizing supply chain management with an ERP system improves the speed, accuracy, and flexibility of supply-risk management.

By building and reinforcing a single source of truth enabled by an ERP system, manufacturers and distributors can have collaborate with other supply chain players. This not only enables improved visibility and coordination across the supply chain but strengthens capabilities in anticipating risk, and managing issues that arise from disruptions as well as growing product complexity.