Before considering an ERP implementation, let’s take a look at three very useful concepts that need to be factored upfront:

-

Kaizen – the most commonly used phrase referring to a slow and steady incremental change. However, no amount of Kaizen of the candle will lead to the development of the light bulb. This brings up our next concept.

-

Kaikaku – this is the radical change that is needed to bring a step change into the organization.

-

Gambatte – this is self-explanatory…Do Your Best!

Now let’s talk about your ERP implementation – is it a big bang project or a longer-term incremental implementation? The answer is probably yes to both. It should be!

Getting your ERP system live is a big bang (“Kaikaku”), but after that, it becomes an ongoing project that you will need to keep working on (“Kaizen”). To ensure the go-live is successful, you would use a proven implementation methodology. For long-term projects, you need a different approach but also using a proven methodology that maintains a constant stream of gradual improvements. This is where the Kaizen method comes in.

Evolution vs. Revolution

Translated from Japanese, Kai means change, and Zen means for the better, Kaizen is an evolutionary methodology. Kaizen is the familiar kind of improvement used when it comes to any continuous improvement – it involves taking your time and effort to work through current processes. Kaizen then requires an organization to implement incremental changes to action the improvement. When applied within a workforce it involves everyone, from managers to floor staff, every day and every location. Kaizen provides a structure of continuous improvement that is constantly used within an organization with minimal risk, yet producing effective results.

In contrast to Kaizen, Kaikaku is a revolutionary method and is for those moments when part of implementing continuous improvement requires the need for a more radical step change. When a problem arises that requires immediate more effective change, usually for a larger project, Kaikaku comes into play. This can be the installation of a software update that will have a large impact on the processes within an organization, quickly reducing waste within the step(s) it is associated with. The results are more immediate, yet the risk is far greater than Kaizen.

Kaikaku

Although Kaikaku is a radical step, this does not mean that proper planning and organization is not required. On the contrary, it is a far more aggressive and riskier step, therefore better planning and understanding is needed. It will be quite difficult to backtrack from a major change in the organization when it fails.

Kaizen

The Kaizen method is based upon continuous incremental improvement. This will occur post the software implementation, and looks at the best fit, ensuring that all of the key staff are trained. It can be seen as extracting maximum value from the investment.

When used properly, it is philosophy and action combined. As a philosophy, it helps to create a culture within an organization where all employees are actively engaged in suggesting and implementing improvements. As an action, it is about organizing activities in critical areas where improvements can be made.

While Kaizen was developed in the manufacturing sector and can be an important catalyst in lean manufacturing strategy as it helps to reduce defects, eliminate waste, improve productivity, and promote innovation, as well as encourage worker involvement, its success is not restricted to manufacturing. It can be applied to any process needing improvements.

There are five foundation elements to Kaizen:

-

Teamwork

-

Personal discipline

-

Improved morale

-

Quality circles

-

Suggestions for improvement

From this, culture can develop which encourages quality, effort, involvement from all employees, willingness to change, and communication.

Kaizen and ERP projects

ERP systems are implemented to improve existing operations or launch new business initiatives, such as digital transformation, or to resolve any other problem facing the organization. To ensure the implementation processes are managed, and the project achieves its goals in terms of scope, time, resources and cost, organizations often use an implementation methodology provided by the ERP vendor. Often this does not fit the organization – each organization has a unique culture and strategic implementation fit. The organization needs to actively participate in aligning the methodology and the organizational culture before implementation begins. Remember that this is the Kaikaku process and the highest risk.

Unfortunately, it’s not uncommon for organizations to think once the ERP system has gone live that the project is finished. The organization is now entering the Kaizen phase, the organization needs to collectively reflect on key processes, and identify areas for improvement ensuring that the organization can continue taking incremental steps to improve its processes.

A major factor in the success of any ERP implementation is the way in which the staff at various levels of the enterprise have been engaged. Again, the implementation is a Kaikaku event which requires far more change management than realized. Once that has been completed, adopting a Kaizen approach and using the elements of teamwork, quality circles and suggestions for improvement, will greatly improve the chances of the project being successful because it will now ensure staff engagement at every level and allow them to adapt to and be comfortable with the changes. Each organization has its own unique change process and rate – exceed this at your own peril!

Implementing a Kaizen philosophy is important, but the action steps that will drive the execution of continuous improvement are equally important.

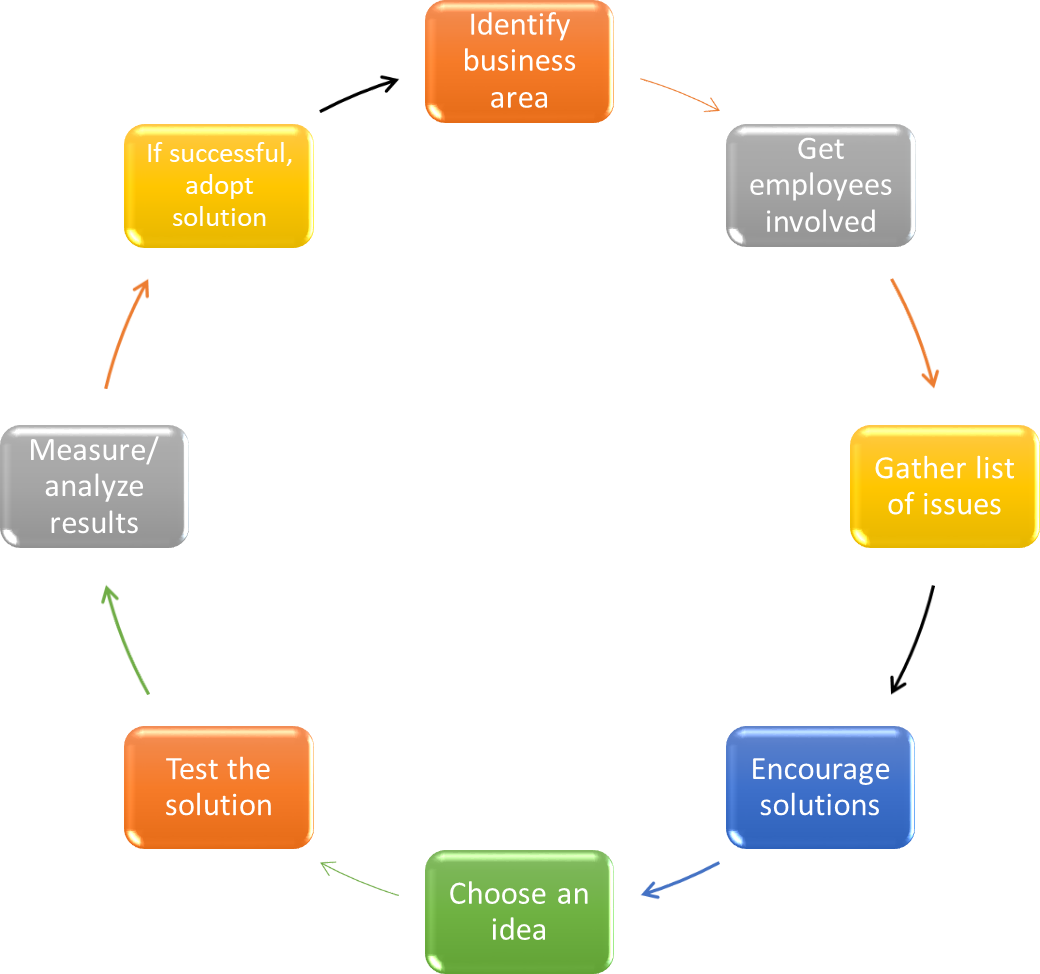

A Kaizen event is a sequence of actions that enable this:

- Set goals

- Review the current state, and develop plans for improvement

- Implement the improvements

- Review and fix what isn’t working

- Report results

- Determine next steps

Kaizen Cycle for Continuous Improvement

The principles that the founder of Kaizen, Masaaki Imai, introduced in 1986 fit well into the concepts that are critical to a successful ERP implementation. These principles are:

- Process-oriented: improve processes to get better results. Both Kaikaku and Kaizen are process-driven activities with clear steps that need to be implemented.

- Maintain and improve standards: without standards, you cannot make improvements, preparation for both phases needs to document these standards to ensure that the objectives set are clear improvements.

- People-oriented: involve everyone from the shop floor to the top floor, and ensure that the unique organizational culture and attitude to change are factored into the process.

How Kaizen differs from other methodologies

Over the years, other methodologies have been trialed in ERP implementations. These include BPR (business process re-engineering), Six Sigma, and Lean, amongst others.

These are summarized in the table below:

| Process | Considerations |

| BPR | Used in major structural and process changes

More technology-oriented Requires major change management effort Decisions made by executives and management |

| Six Sigma | Provides tools and strategies to reduce defects and variability

Uses statistical techniques to develop quantified targets |

| Lean | Focuses on the removal of waste (i.e. anything that does not add value to the customer) by looking at aspects like inventory, waiting, defects, excess production

Aims to increase process speed and quality |

| Kaizen | Improve business as a whole by establishing a standard way of work that encourages thinking creatively throughout the enterprise, improving efficiency, and reducing waste

Look anywhere for changes that can be made to improve the business |

Kaizen is where the organization takes ownership of the new implementation and gets it to deliver exactly what that organization requires from it i.e. address their unique business requirements. Another organization in the same industry will require a different set of outcomes from their implementation.

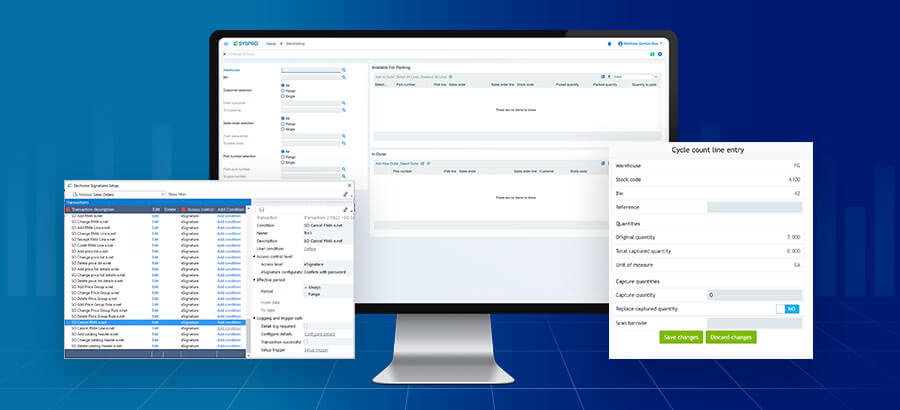

How ERP can support Kaizen

ERP systems can support continuous improvement by establishing process and quality standards, order management, shopfloor operations, goods storage and dispatch.

Reports and analytics in your ERP system will help you to identify areas where improvements can be made, and then measure if the improvements have made the desired impact. It cannot only be the senior management who sees and uses this information. A Kaizen approach must allow all employees access to the information so they can propose their own changes – after all, they work in that process on a daily basis and have a far more detailed knowledge of how it operates.

“Respect for the individual” in Lean is the drawing out and challenging of the process to better it for the organization by the users of the process. Unfortunately, this is seldom attempted.

An ERP implementation is neither a trivial or short-term activity. Once your ERP system is implemented, the organization is in it for the long-term. To ensure that long-term benefit is extracted, the organization must ensure that:

- Staff is continuously engaged, and

- A culture and set of actions that encourage and promote continuous and gradual improvement is developed in all areas where improvements can be made.

Using the Kaizen approach is one way you will keep reaping rewards from your ERP system, and avoid the situation when you discover that your business has changed but your ERP system has not.