Digital transformation is the latest trend, and for good reason. Being a successful food or beverage manufacturer in 2019 is no small feat. It requires an efficient supply chain and demand management, quality control, and a willingness to adapt to an ever-changing industry.

That being said, let’s explore why digitalized operations is essential to today’s food and beverage manufacturers:

1 – A Customized Traceability System

The processes behind the inspection and regulation of food and beverage products are changing, which means that a willingness to adapt and innovate is critical to your operations. Although food law is used in a singular term, it is recognized that in many countries more than one law may exist which contains provisions for ensuring safe and quality food production. Implementation of food laws and regulations is essential and in many countries food and beverage manufacturers are also required to implement a verified traceability system for transparency.

This shift from prescriptive regulations can be a good thing since there is no officially recognized, set-in-stone traceability program. As we’ve covered previously, specialized systems are imperative since your business operates with unique complexities and challenges to face. You have the freedom to seek out a custom solution that is optimized to suit your business’ specific needs. Key benefits include greater potential for improving value chain efficiencies and lowering costs. Also, expect greater effectiveness at isolating and preventing contaminated products from reaching consumers. The latter could do wonders for your brand equity – something invaluable in an age when competitors are more aggressive than ever to secure the trust of prospective customers.

2 – Consumers Demand Change

If there’s one thing that can help your business sink or swim, it’s a reputation. Greater transparency and accountability are understandably being demanded by the average consumer, driven by an increase in recalls and investigative reports seeking to protect shoppers. Therefore, people want quick, convenient and easy access to information about your company. Specifically, they seek clarification on what goes into that meal on the dinner table, your values, and the ethicality of your current practices. Long story short, you need to be willing to accommodate their requests. Otherwise, you could be gambling with your reputation and run the risk of lower profits due to reduced consumer trust.

3 – Improved Management Efficiency

A recall due to mislabelling or a widespread health and/or safety risk can happen at any time, no matter how proactive your supply chain management system is. Your business also needs to be able to act fast when it comes to unexpected hiccups or changes in operations such as ingredient price fluctuations or a spike in product demand. Cost reductions aren’t limited to reducing financial expenses, either – they also involve mitigating potential damage to your brand reputation as well as catching manufacturing anomalies in real time during the production process. This requires a quick, appropriate reaction to unexpected situations. With that need to expect the unexpected, it’s a good idea to implement an innovative solution that can address problems before or as they’re unfolding rather than once that damage has taken its toll.

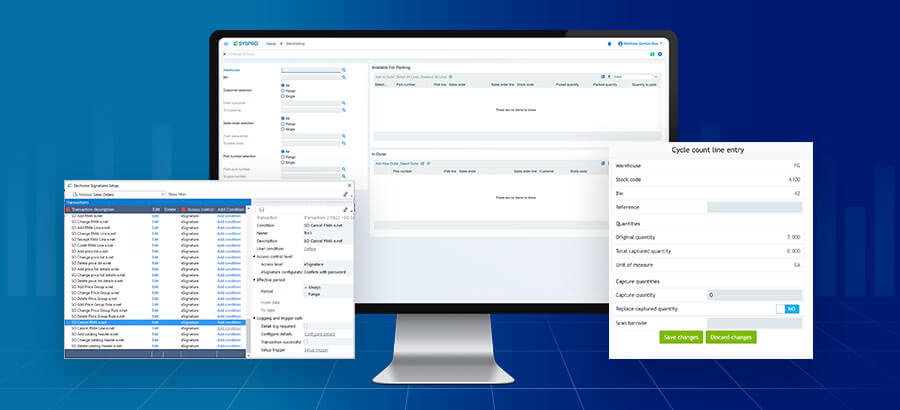

This is where digitalized supply chain management systems could literally save your business. Consider SYSPRO’s ERP solutions for food and beverage manufacturers, for instance. If you’re concerned about optimizing margins, reducing giveaway and ensuring fewer QA mistakes, it’s a streamlined way to keep tabs on everything from recipe quality control to full compliance, and purchasing and inventory management. Reliance on technology to keep operations smooth and under control is higher than ever in times of crisis or otherwise.

Today’s food sofware manufacturers don’t merely rely on innovation and digitalization because it’s the latest trend. It’s an outright requirement in order to maximize efficiency and cost savings. With the onset of Industry 4.0 and mandatory traceability, manufacturers have little choice but to modernize or lose market share. Tech will continue to play an essential role in how we manage supply chains, especially when working with perishable products that need to get out quickly without skipping compliance or QA-related steps along the way. Add customer demands for something new and unique as well as the fact that there is no “off” button when it comes to this type of business, and you have an ever-growing collection of challenges that need to be addressed.